Ring Stiffness Testing Machine for Pipes and Fittings – High Precision and Reliable Testing for Plastics, Pipes & More

$7,000.00 – $9,400.00

The Microcomputer-Controlled Ring Stiffness Testing Machine is designed according to international industry standards, specifically developed for pipe stiffness testing. It complies with the latest standards for thermoplastic pipes and is widely used in industries like steel metallurgy, construction materials, aerospace, and mechanical manufacturing for pipe ring stiffness testing.

Description

📌 Microcomputer-Controlled Ring Stiffness Testing Machine Overview

The Microcomputer-Controlled Ring Stiffness Testing Machine is designed according to international industry standards, specifically developed for pipe stiffness testing. It complies with the latest standards for thermoplastic pipes and meets global standards such as ASTM. It is widely used for accurate ring stiffness testing of various materials.

Our company’s Microcomputer-Controlled Testing Machine integrates advanced foreign control technology with a superior transmission system. It is equipped with high-precision AC servo motors, servo drivers, and ball screws to form the main unit. The control system, independently developed by our company, uses high-precision components along with high-accuracy pressure and deformation sensors. The machine is aesthetically designed, easy to operate, with stable and reliable performance, low noise, pollution-free, and high efficiency, offering a wide speed adjustment range. This machine is widely used in industries such as steel metallurgy, construction materials, aerospace, mechanical manufacturing, electrical cables, rubber plastics, textiles, and home appliances for material testing and analysis. It is an ideal testing device for schools, industrial enterprises, technical supervision, and commercial inspection departments. It is suitable for the ring stiffness testing of thermoplastic plastic pipes, fiberglass pipes, double-wall corrugated pipes, fiberglass-reinforced pipes, spiral wound pipes, PE pipes, PVC pipes, PPR pipes, and other types of pipes.

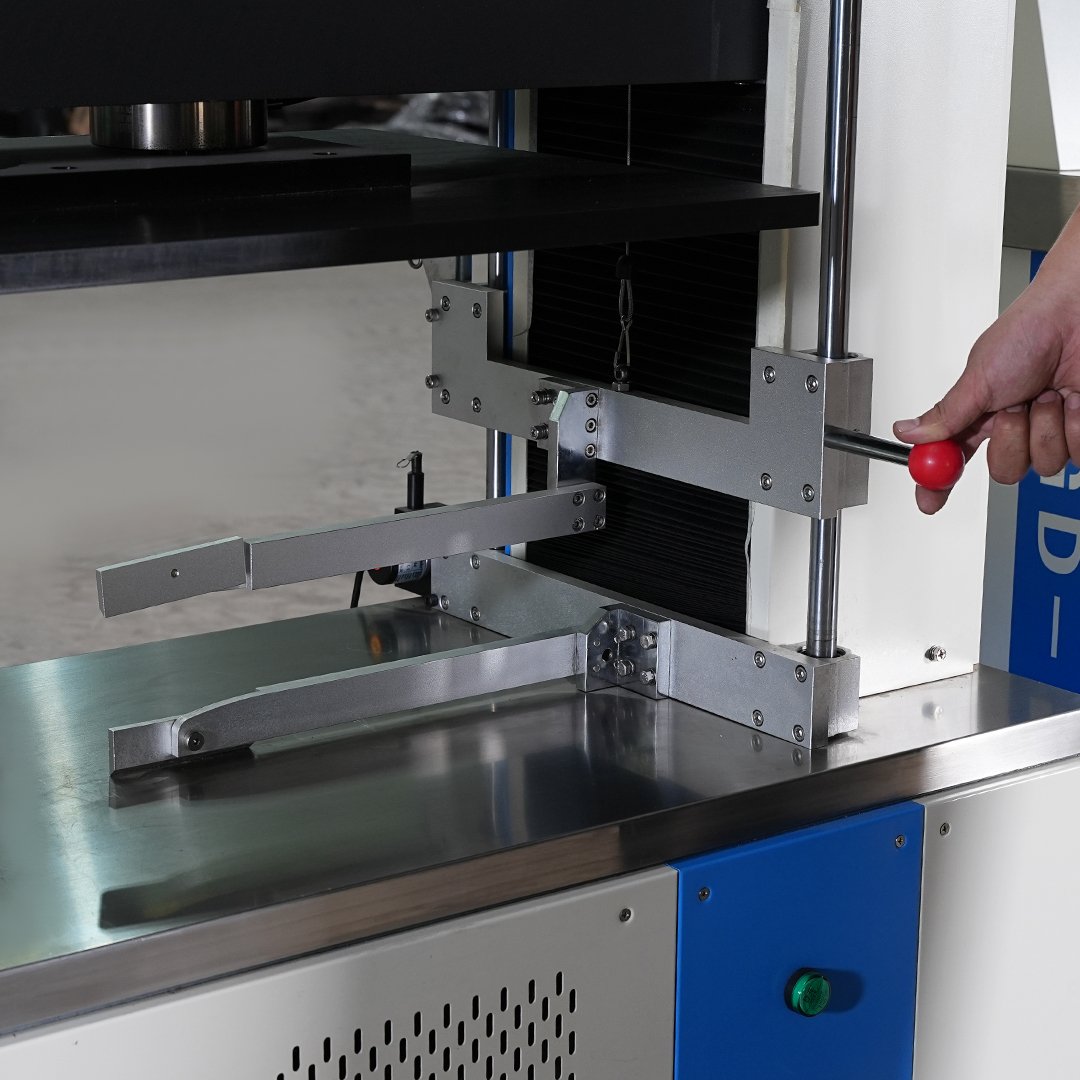

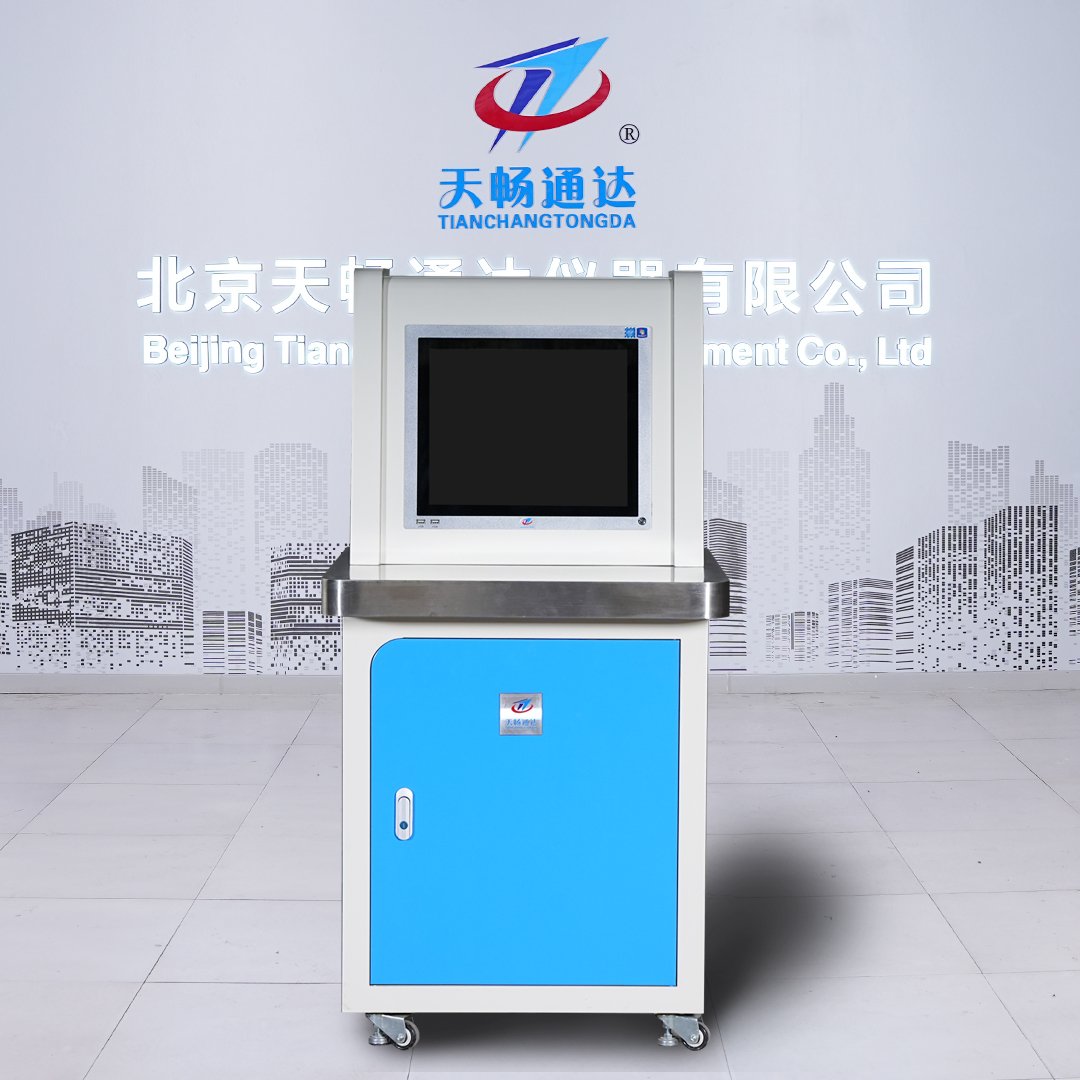

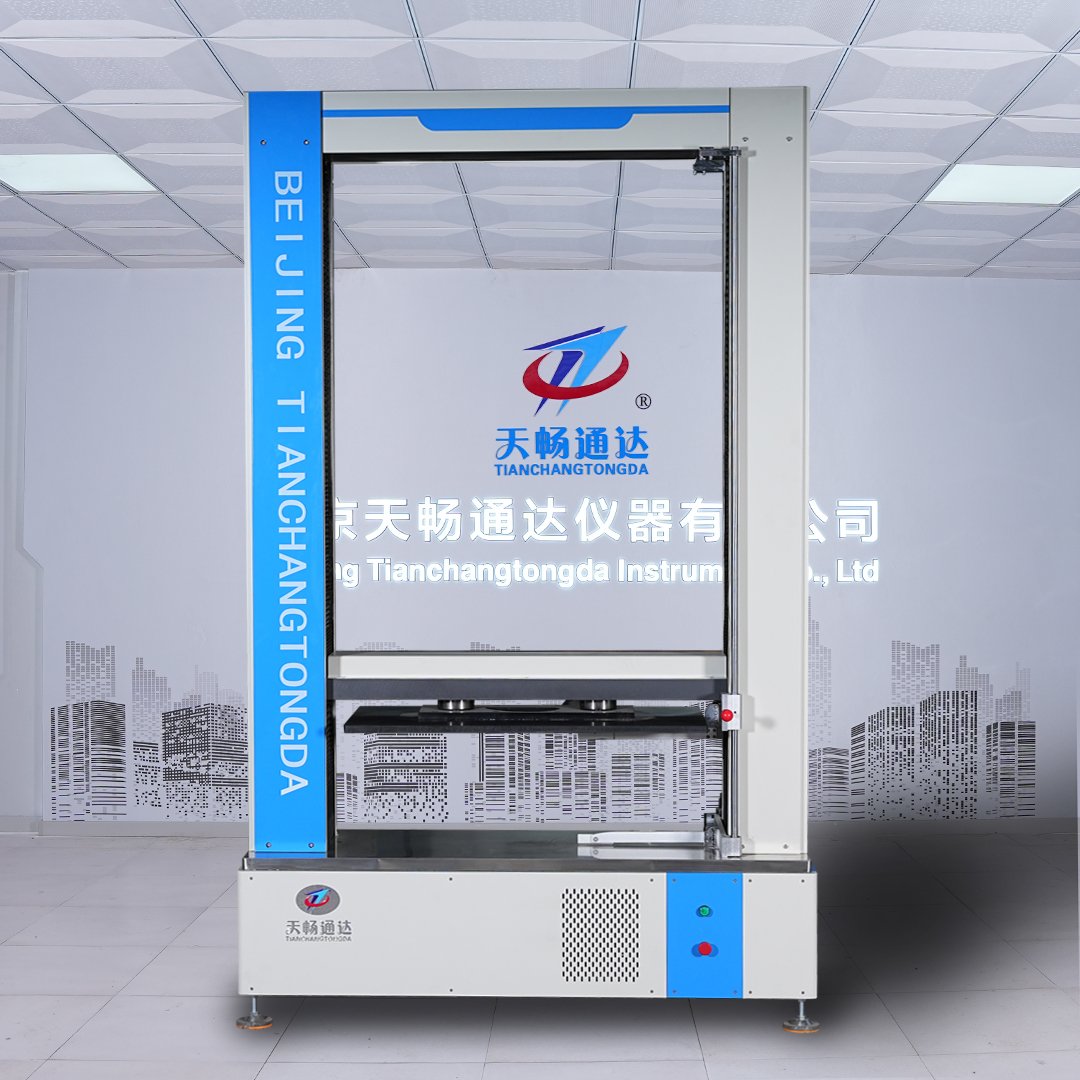

📌 Product Details & Operation Display

Image 1

Image 2

Image 3

Image 4

⚙️ Key Features

- The machine adopts a four-column frame structure with dual space. The speed control system for both the pulling and pressing actions uses a servo speed control system and servo motor, ensuring stable and reliable performance with mechanical protection features such as overcurrent, overpressure, and overload protection.

- The transmission part uses an arc-shaped synchronous toothed belt, with precision ball screw drive, ensuring smooth transmission, low noise, and high efficiency.

- The universal joint employs a cross-pin structure and includes an angle-limiting function. This design facilitates sample clamping, ensuring the test’s concentricity, and effectively eliminates the impact of irregular samples on the sensors.

- Equipped with a specialized ring stiffness deformation measurement device, the machine provides more accurate deformation results.

📊 Technical Parameters

- Maximum Test Force: 50KN

- Measurement Range: 2%–100% of the maximum test force (0.4%-100%)

- Test Machine Accuracy Level: Class 1

- Test Force Accuracy: Better than ±1% of the indicated value

- Beam Displacement Measurement: Resolution of 0.01mm

- Deformation Accuracy: Better than ±1%

- Speed Adjustment Range: 0.01–500mm/min (Width: 1000mm)

- Test Space: 2000mm (customizable)

- Mainframe Type: Gantry frame structure

- Mainframe Dimensions: 156×51×306 (Unit: cm)

- Control Cabinet Dimensions: 80×75×137 (Unit: cm)

- Weight: Approx. 600KG

- Operating Environment: Room temperature to 45°C, humidity 20%-80%

💡 Why Choose Us?

Tianchang Tongda Instruments Co., Ltd. is a trusted test equipment manufacturer in China,

with over 20 years of experience in industrial testing and quality control.

We specialize in high-precision equipment for pipes, steel structures, rebar, cables, insulation materials, and more.

Our instruments are widely used in laboratories, manufacturing plants, universities, and third-party inspection agencies.

As an ISO-certified company, we ensure all products meet international standards such as ISO, ASTM, and EN.

From installation to remote support, we deliver reliable service and lasting technical assistance.

Our sales network covers all provinces in China and continues to grow globally.

Clients in Southeast Asia, the Middle East, and Europe rely on us for accurate and efficient testing solutions.

| ✅ | 20+ years of manufacturing experience |

| ✅ | ISO, ASTM, EN standard compliance |

| ✅ | Used by top labs and research centers |

| ✅ | Full after-sales support and fast delivery |

| ✅ | Customized testing solutions for your needs |

Informations complémentaires

| Poids | ND |

|---|---|

| Dimensions | ND |

| 规格 | HGD-1500, HGD-2000, HGD-2500 |

Avis

Il n’y a pas encore d’avis.