Rebar Bend and Reverse Bending Testing Machine – High Precision for Reinforced Concrete Bending Performance Evaluation

$3,600.00

The Rebar Bend and Reverse Bending Testing Machine is used to test the performance of rebar at different bending angles, widely used in the construction and steel industry to ensure the quality and reliability of rebar.

9999 en stock (peut être commandé)

Description

📌 Rebar Bend and Reverse Bending Testing Machine Overview

The Rebar Bend and Reverse Bending Testing Machine is used to test the bending performance of rebar in a plane, especially suitable for rebar bending testing in the construction industry.

This equipment’s main technical parameters and standards comply with YB/T5126-2003 « Test Methods for Bending and Reverse Bending of Reinforced Concrete Rebar, » and it is widely used in steel production, construction, and other industries.

The Rebar Bend and Reverse Bending Testing Machine is an essential device for verifying the reverse bending performance of threaded rebar in steel mills and construction units.

This machine can perform rebar bending tests not only in factories but also conduct on-site rebar bending operations at construction sites, achieving seamless integration of rebar bending testing and construction functions.

This equipment plays a crucial role in improving construction efficiency and ensuring construction quality, making it an ideal choice for rebar performance evaluation and quality control.

The Rebar Bend and Reverse Bending Testing Machine is designed to be simple and easy to operate, capable of accurately measuring the bending and reverse bending performance of rebar to meet the testing requirements for different rebar specifications. The equipment supports bi-directional bending testing, i.e., both forward and reverse bending, to meet testing needs in different working conditions. Its compact structure and easy portability allow it to be quickly deployed even at construction sites.

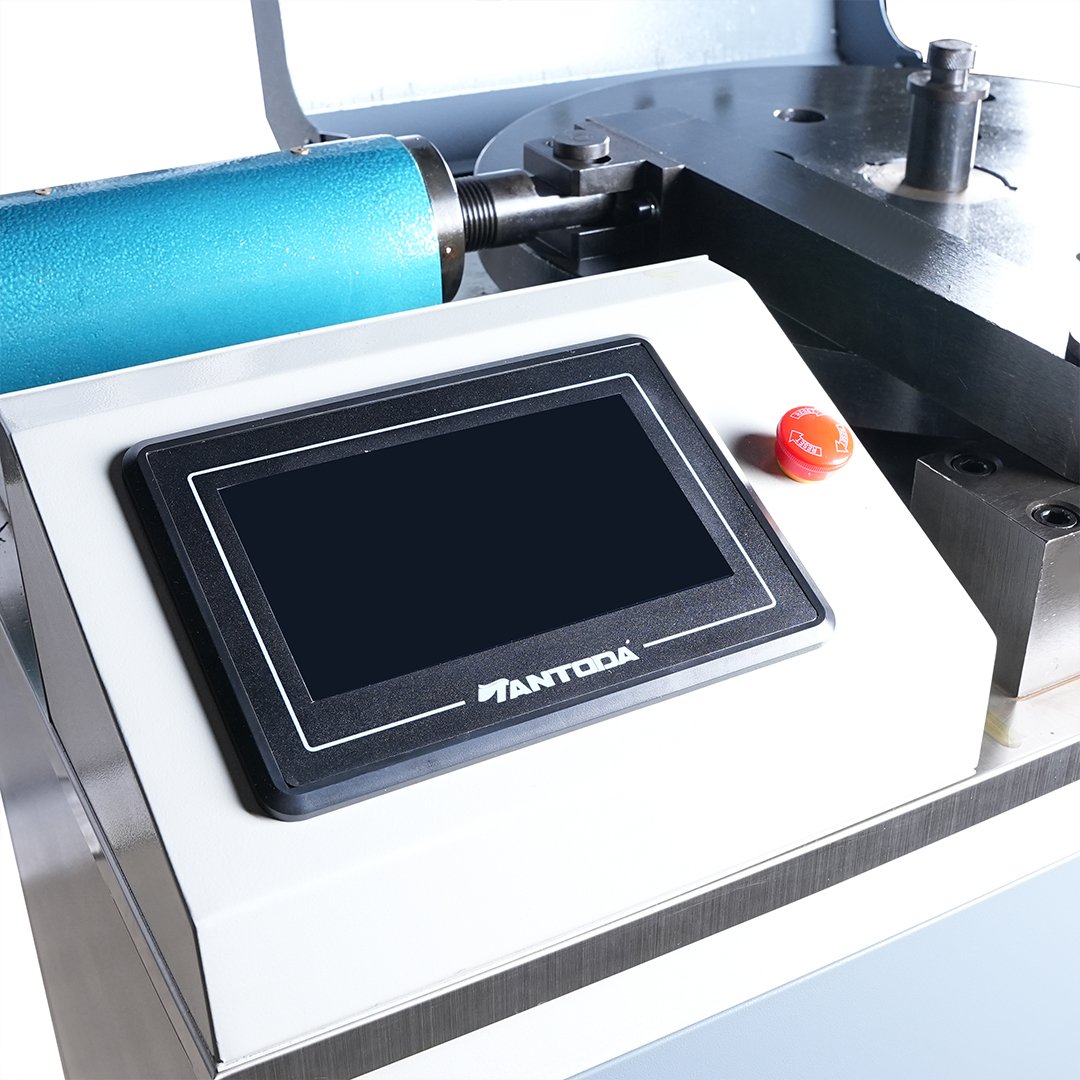

The testing machine adopts high-precision sensors, providing accurate angle and force measurements, ensuring the reliability and consistency of test results. Dual sensor displays ensure that the angles are precise, and the bending angle is displayed clearly, allowing operators to easily read and accurately evaluate the rebar bending precision.

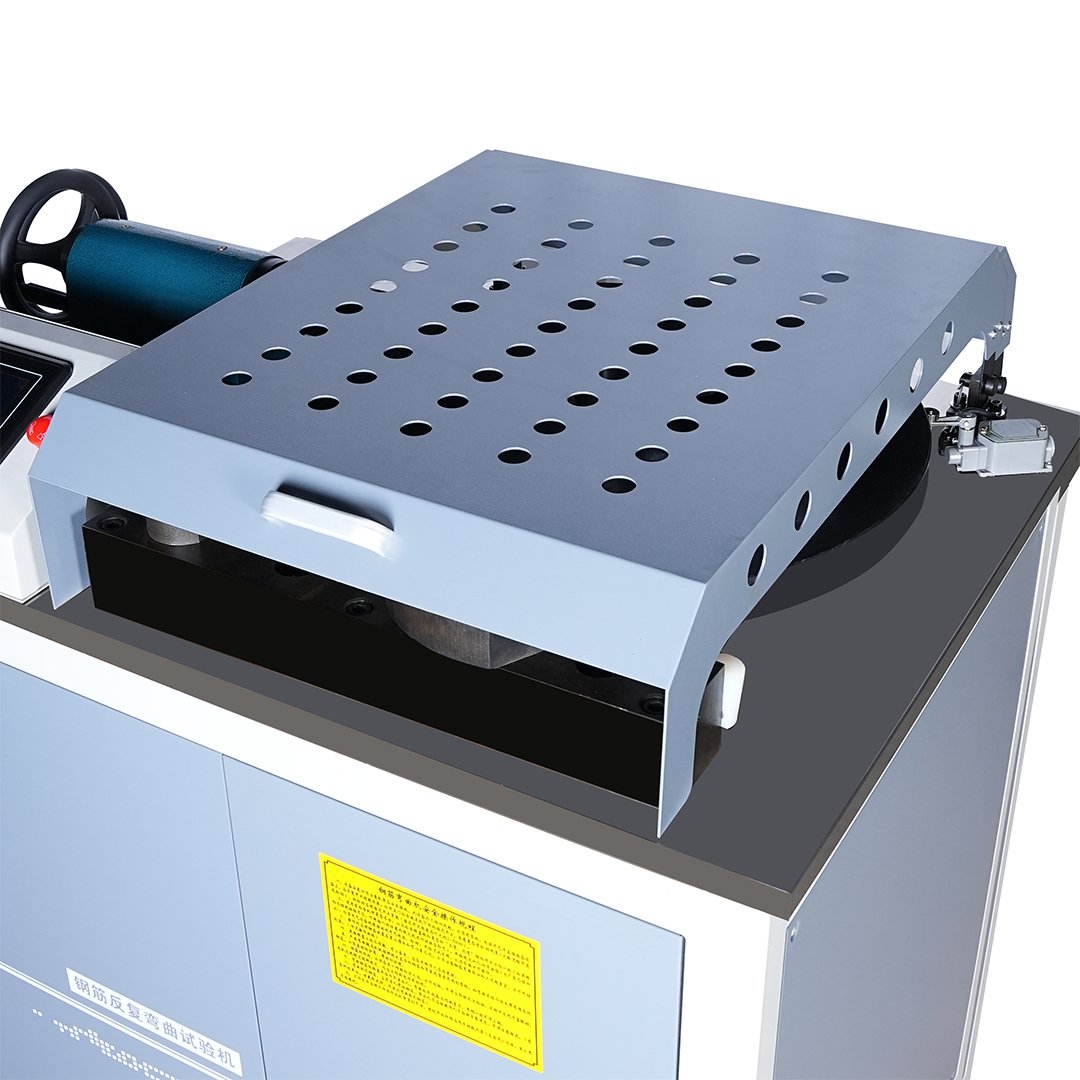

The equipment has an adjustable speed function, and can perform both forward and reverse bending, running smoothly with low noise. It has a long service life, making it suitable for high-intensity, long-term use environments. No fixed setup is required, and it is easy to operate with a pin-type device design and a semi-circular hollow core. The equipment is lightweight, making it easy to deploy and operate quickly on-site, particularly suitable for rebar bending operations at construction sites.

📌 Product Details & Operation Display

🔧 Operating Platform Details

⚙️ Top Area Details

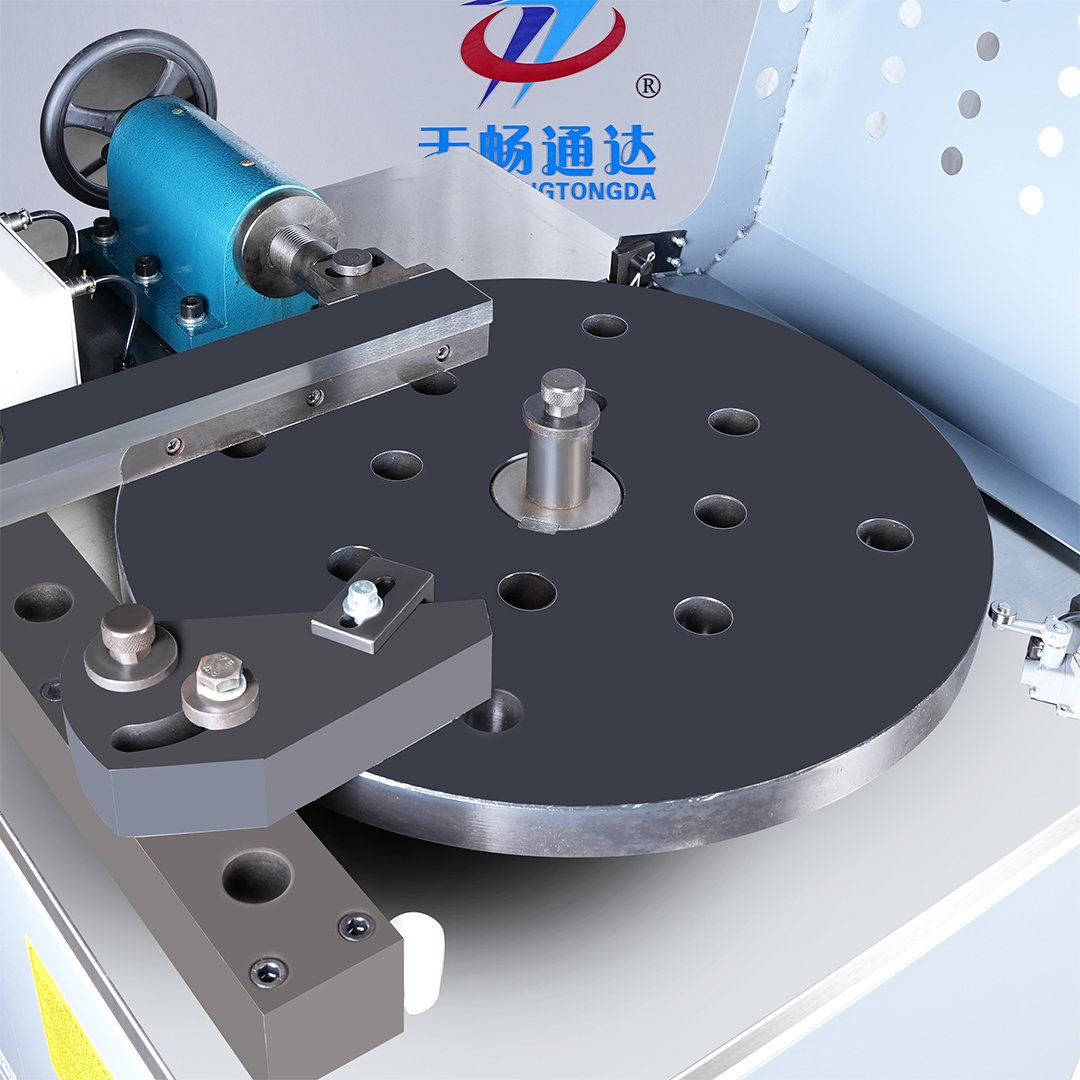

🔘 Working Area Details

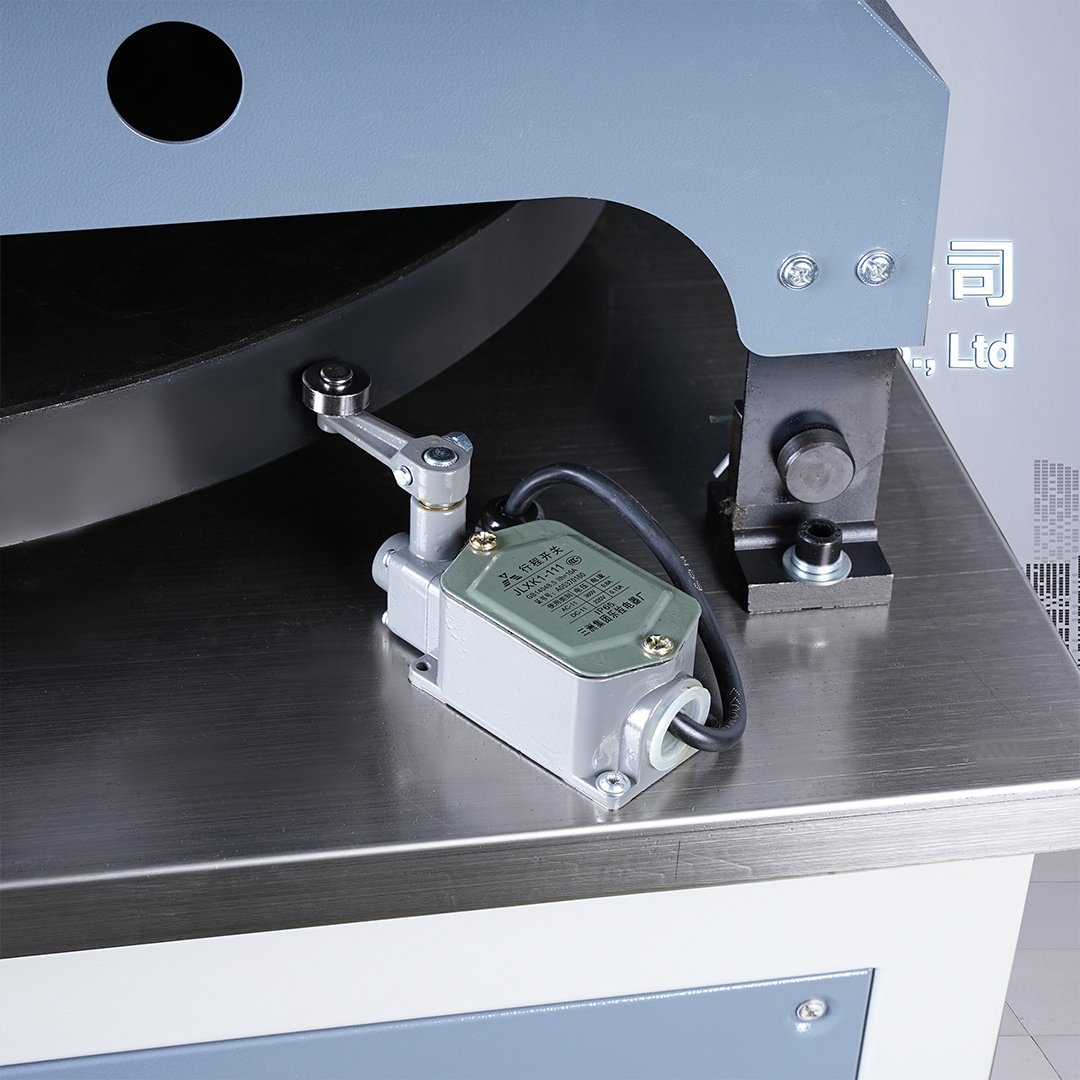

🔘 Limit Switch Details

⚙️ Key Features

- Dual-sensor display: The angle is accurate, and the bending angle is displayed clearly in digital format.

- Speed is adjustable, both forward and reverse bending can be performed smoothly. The machine operates steadily with low noise, ensuring reliability and long service life.

- No fixed installation required, easy to operate, with a pin-type detachable semi-circular hollow bending mandrel. The mandrel is lightweight and easy to handle.

- Equipped with a protective cover, the design ensures improved safety for users during operation.

📊 Technical Parameters

- Rebar Bending Diameter Range: Ø6- Ø40mm

- Forward Bending Angle of Rebar: Adjustable from 0° to 180°

- Reverse Bending Angle of Rebar: Adjustable from 0° to 180°

- Working Disk Speed: ≤3.7r/min

- Roller Center Distance: 165mm

- Working Disk Diameter: Ø580mm

- Motor Power: 1.5KW

- Standard Bending Mandrel Set: 1 set (included)

- Machine Dimensions (Length × Width × Height): 1050 × 740 × 1170 (mm)

- Machine Weight: Approximately 700Kg

💡 Why Choose Us?

Tianchang Tongda Instruments Co., Ltd. is a trusted test equipment manufacturer in China,

with over 20 years of experience in industrial testing and quality control.

We specialize in high-precision equipment for pipes, steel structures, rebar, cables, insulation materials, and more.

Our instruments are widely used in laboratories, manufacturing plants, universities, and third-party inspection agencies.

As an ISO-certified company, we ensure all products meet international standards such as ISO, ASTM, and EN.

From installation to remote support, we deliver reliable service and lasting technical assistance.

Our sales network covers all provinces in China and continues to grow globally.

Clients in Southeast Asia, the Middle East, and Europe rely on us for accurate and efficient testing solutions.

| ✅ | 20+ years of manufacturing experience |

| ✅ | ISO, ASTM, EN standard compliance |

| ✅ | Used by top labs and research centers |

| ✅ | Full after-sales support and fast delivery |

| ✅ | Customized testing solutions for your needs |

Informations complémentaires

| Poids | 715 kg |

|---|---|

| Dimensions | 105 × 74 × 117 cm |

Avis

Il n’y a pas encore d’avis.