Automatic Soil Specimen Molding and Demolding Machine for Soil Testing and Efficient Civil Engineering Applications

$3,900.00

The Fully Automatic Unconfined Specimen Demolding Integrated Machine works with the Multifunctional Electric Impact Compactor. It features hydraulic drive for smooth operation, suitable for high-strength specimen demolding, reducing labor intensity, and improving efficiency.

9999 disponibles (puede reservarse)

Descripción

📌 Automatic Soil Specimen Molding and Demolding Machine Overview

The Automatic Soil Specimen Molding and Demolding Machine is a high-efficiency geotechnical testing device designed for soil testing. It is widely used in highway engineering, roadbase construction, and the strength testing of inorganic mixture stability in soil. The machine features a hydraulic drive system, ensuring smooth and reliable operation, especially suitable for high-strength soil specimen demolding.

Compared to traditional mechanical demolding machines, the Automatic Soil Specimen Molding and Demolding Machine offers greater power, higher efficiency, lower noise, and a longer service life. It can meet the demolding requirements for high-strength specimens, such as cement mixtures. The machine’s automated design allows the molding and demolding processes to occur simultaneously on the same workbench, eliminating the need to transport molds, significantly reducing labor intensity and improving operational efficiency.

The hydraulic drive system optimizes the power output, providing stable operation and reducing noise. Its simultaneous molding and demolding operation increases efficiency by allowing both processes to be completed on the same workbench, avoiding the inconvenience and complexity of traditional manual operations.

The Automatic Soil Specimen Molding and Demolding Machine is not only used for soil specimen demolding but also widely applied in the demolding of cement mixture specimens, soil strength testing, and other geotechnical testing tasks. The machine integrates an intelligent control system, enhancing efficiency and precision in operation. It is especially suitable for highway engineering construction, roadbase testing, and inorganic mixture stability in soil strength testing.

The fully automated operation significantly reduces the time and labor required for traditional manual operations. The automated control system improves testing accuracy, minimizing human errors and enhancing reliability. The machine’s low-noise design and high performance make it ideal for both laboratory and field operations in high-intensity environments.

The Automatic Soil Specimen Molding and Demolding Machine is an indispensable high-efficiency device for geotechnical testing. Its automated, efficient design makes it the ideal choice for soil specimen demolding and geotechnical testing, widely used in highway engineering, soil strength testing, and soil testing fields. The machine can significantly improve testing accuracy and work efficiency while reducing labor intensity, making it a key tool for modern civil engineering testing.

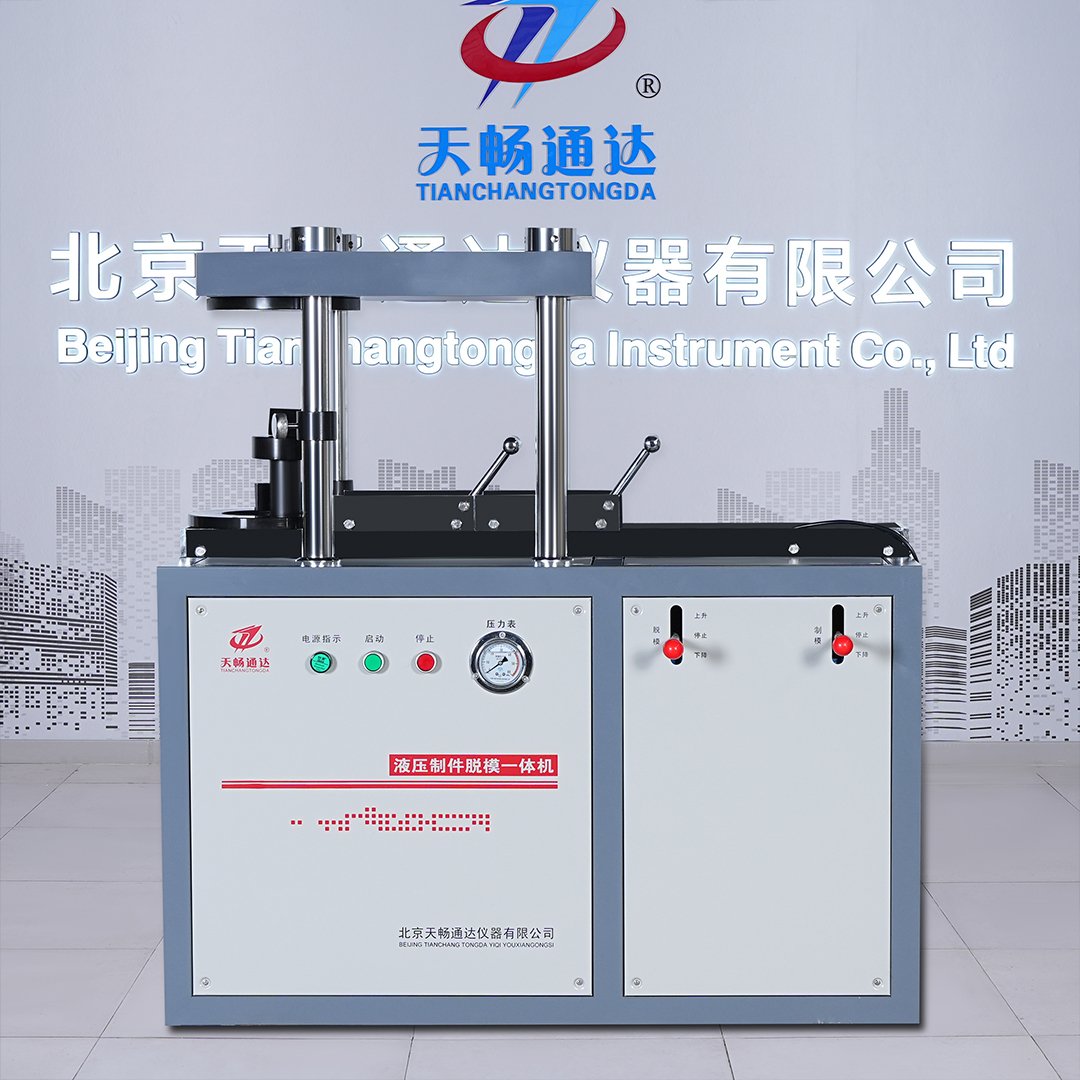

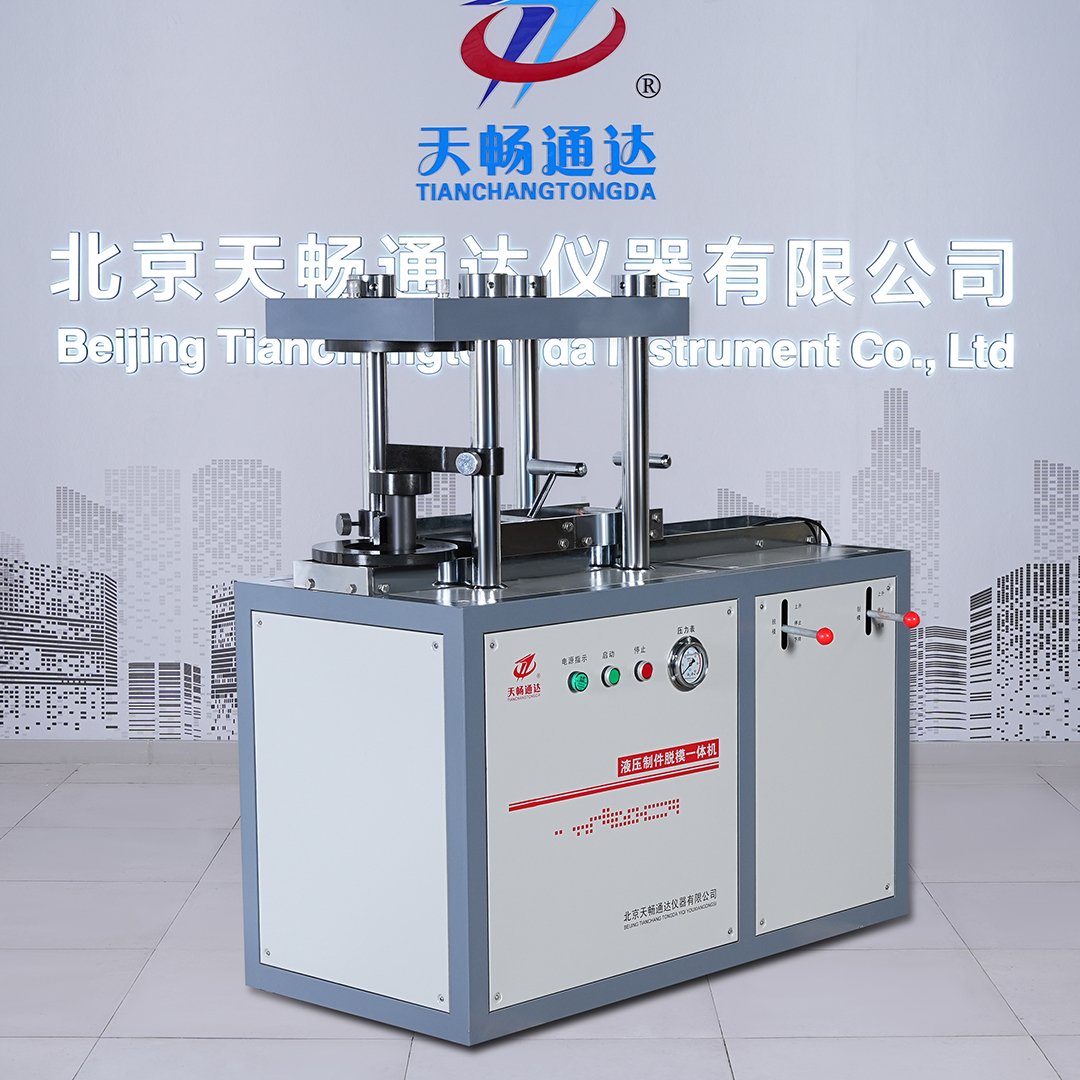

📌 Product Details & Operation Display

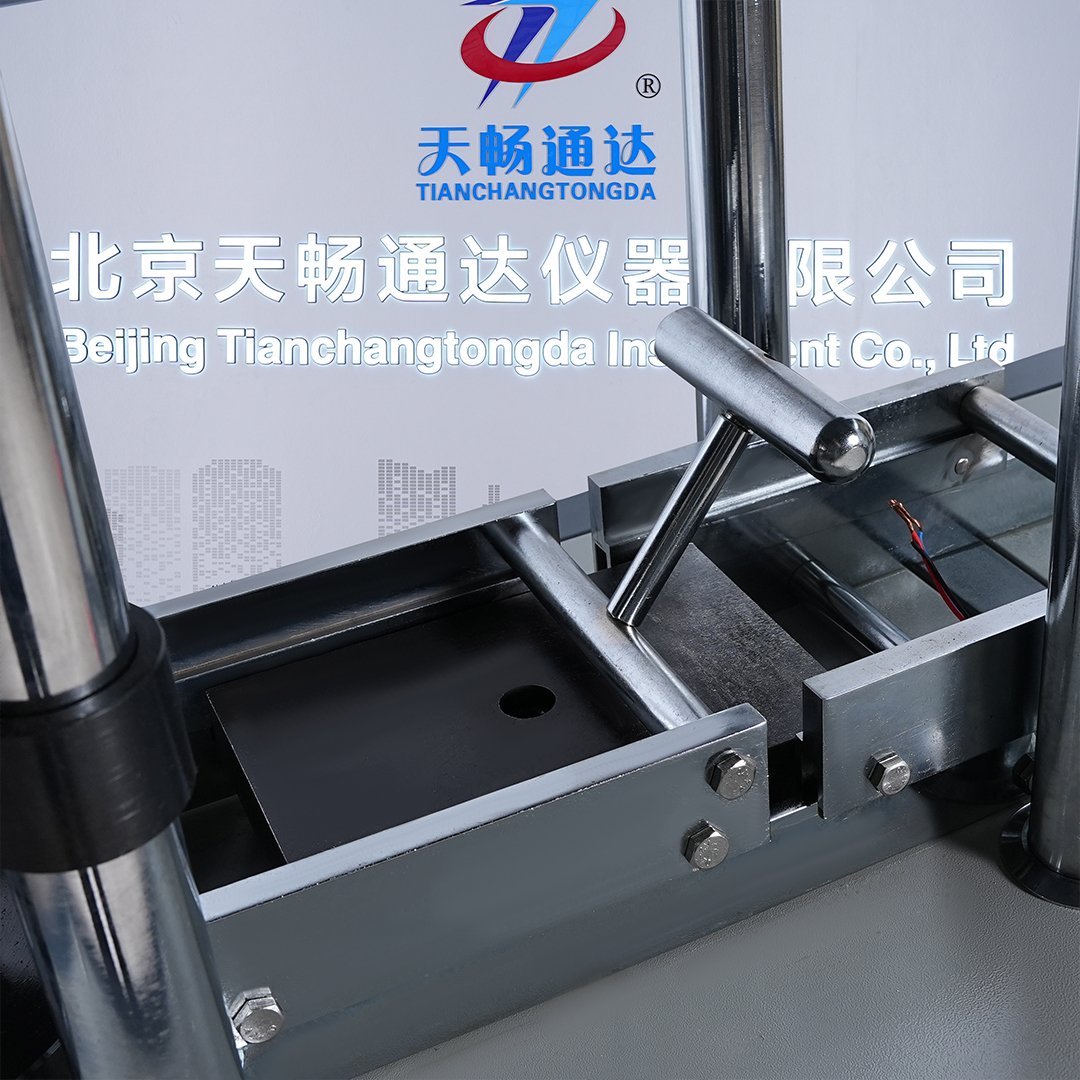

🔧 Operating Area Details

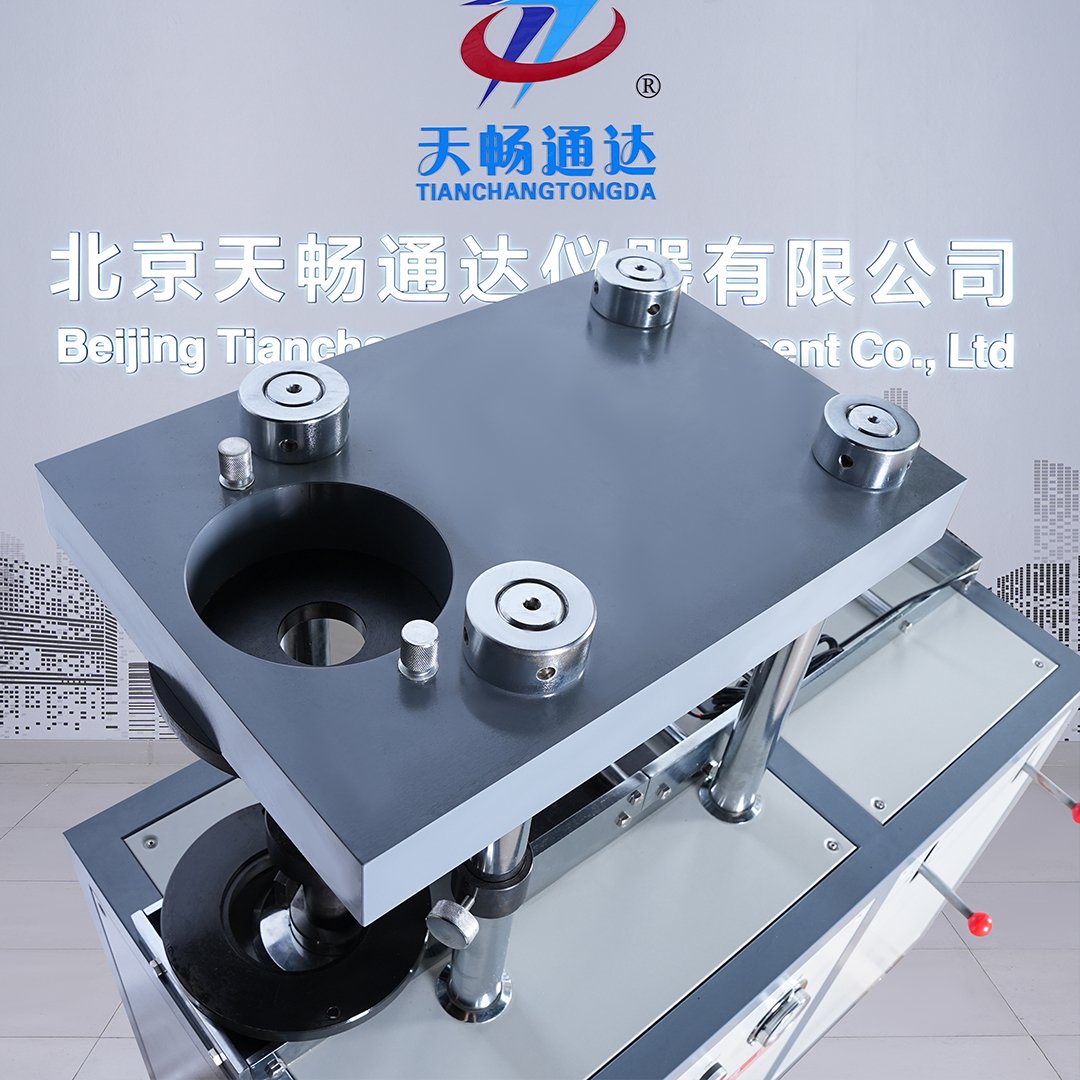

⚙️ Top Area Details

🔘 Working Area Details

⚙️ Key Features

- Compact structure, reasonable layout, realizing a dual-purpose function for both forming and demolding with one machine.

- Hydraulic system uses advanced plunger pumps and specimen holding pressure system, improving specimen quality and reducing wear.

- Allows simultaneous specimen forming on the right side and demolding on the left side on the same workbench, reducing labor intensity and improving operational safety.

- The forming and demolding processes are independently operated, improving work efficiency.

- The machine can stop and automatically hold pressure during testing.

- Developed to overcome the shortcomings of similar products, suitable for molding various specimens with diameters up to 152mm and a height of up to 230mm.

📊 Technical Parameters

- Maximum Forming Force: 1000KN (pre-set, do not adjust)

- Maximum Demolding Force: 300KN

- Forming Speed: 80mm/min

- Demolding Speed: 200mm/min

- Maximum Forming Stroke: 150mm

- Maximum Demolding Stroke: 300mm

- Motor Power: 380V/1.5KW

- Oil Pump Rated Pressure: 31.5MPa

- Oil Pump Nominal Displacement: 2.5ml/r

- Oil Pump Rated Speed: 1500r/min

- Total Weight: 450Kg

💡 Why Choose Us?

Tianchang Tongda Instruments Co., Ltd. is a trusted test equipment manufacturer in China,

with over 20 years of experience in industrial testing and quality control.

We specialize in high-precision equipment for pipes, steel structures, rebar, cables, insulation materials, and more.

Our instruments are widely used in laboratories, manufacturing plants, universities, and third-party inspection agencies.

As an ISO-certified company, we ensure all products meet international standards such as ISO, ASTM, and EN.

From installation to remote support, we deliver reliable service and lasting technical assistance.

Our sales network covers all provinces in China and continues to grow globally.

Clients in Southeast Asia, the Middle East, and Europe rely on us for accurate and efficient testing solutions.

| ✅ | 20+ years of manufacturing experience |

| ✅ | ISO, ASTM, EN standard compliance |

| ✅ | Used by top labs and research centers |

| ✅ | Full after-sales support and fast delivery |

| ✅ | Customized testing solutions for your needs |

Información adicional

| Peso | 450 kg |

|---|

Valoraciones

No hay valoraciones aún.